By PATRICK GILLESPIE

A project five years in the works is bringing in results to Clay County, as the St. Johns River Water Management District, County, and Sustainable Water Infrastructure Group, LLC are realizing the results of removing residual phosphorus from treated wastewater effluent with their Doctors Lake Phosphorus Elimination System (PES).

In September 2018, The District sought proposals to remove phosphorus from the lake, which is in the Lower St. Johns River system, with funding appropriated by the Florida Legislature. Sustainable Water Infrastructure Group, or SWIG, was awarded the contract. To-date, the company reports that more than 6,400 pounds of phosphorus has been removed using their technology. In addition, the project has resulted in nearly 54 percent of total nitrogen being removed.

“The District and our partners have been actively working to improve water quality in the Doctors Lake Basin, and the Doctors Lake Advanced Effluent Treatment Project is a part of that effort,” said St. Johns River Water Management District Supervising Professional Engineer Marc Van Heden. “Since its inception, the project has effectively removed 6,400 pounds of phosphorus, efficiently delivering excellent water quality results.”

The contract was designed as a “Pay for Performance” contract whereby phosphorus removal from treated wastewater effluent was independently measured, prior to reclaimed water reuse or discharge into the river.

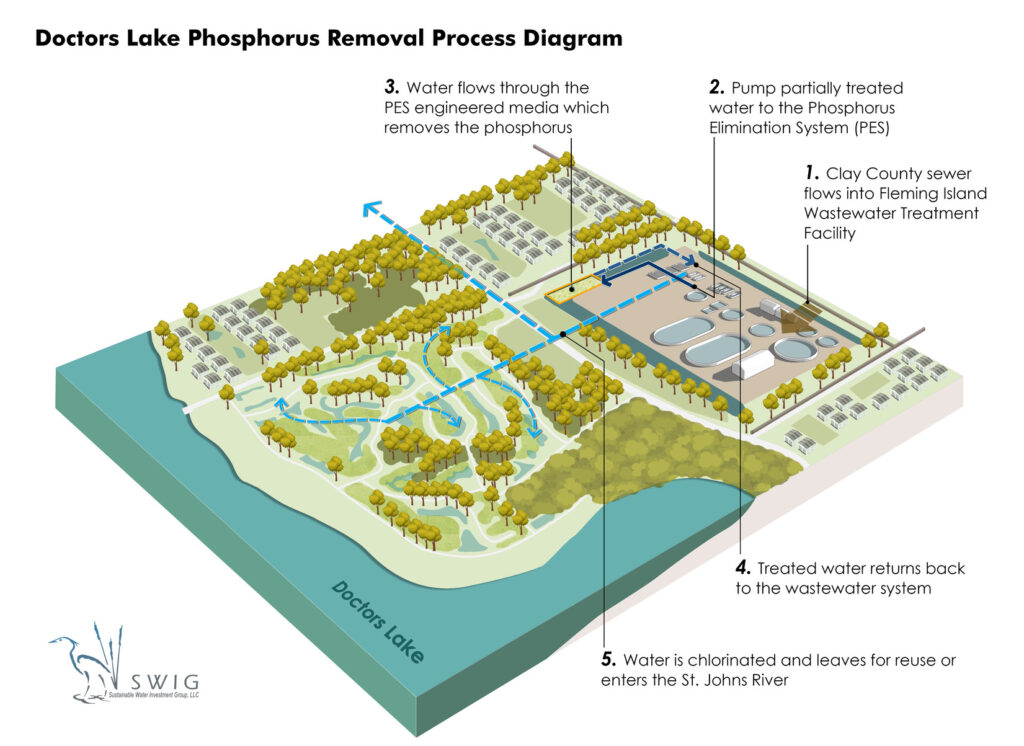

The PES distributes wastewater inflow over an innovative passive bio-filtration media designed to capture phosphorus through an adsorption process and water is then returned for chlorination and either used as reclaimed water or discharged into the St. Johns River. The system works as a “bolt-on” system to the Clay County Utility Authority Fleming Island Regional Wastewater Treatment Plant. SWIG permitted and constructed its facility within nine months during the COVID 19 pandemic.

Water from the PES is sampled daily, which allows for constant data and adjustments as needed. SWIG’s permitting and construction in a short timeframe is a result of simple construction methods that can be easily replicated, according to SWIG COO Mark Merkelbach. The company has a second project with the District for the Black Creek Water Resource Development Project, which is designed to remove tannins before recharging the Upper Floridan Aquifer. This PES variant treats up to 10 million gallons of water per day to restore historically low water levels in the lakes in Keystone Heights.

“The system’s flexible modular design and simple construction allows it to be easily scaled to meet project treatment needs from rural to dense urban applications,” he said.

How Does the Doctors Lake PES System Work

The system contains multiple treatment cells that are dosed using a simple water distribution system and gravity underdrain. Pumps are used to distribute and return treated water back to the wastewater treatment plant.

The system is constructed like a layer cake, where the PES media is laid on top of the gravel underdrain and is set at an elevation to typically match the existing ground surface elevation, according to SWIG. It comprises roughly 1 acre and treats an average of 1.4 million gallons per day.

Keeping the system low to the ground keeps it from being susceptible to wind damage during hurricanes. The facility is planted with wetland plants, the roots of which create macropores in the media which in turn help to maintain high infiltrations rates. The fully automated system is capable of sustaining infiltration rates of over 6 inches per hour which results in treating 5 to 6 feet of water in a 24-hour period.

The SWIG PES requires much less space than treatment wetlands, which typically treat inches per day. This results in a smaller footprint to achieve similar pollutant loads. Furthermore, SWIG reports that its system tolerates dry periods when no water is available, curbing nutrient release, unlike treatment wetlands and stormwater treatment areas. Media is replaced when the media has fully adsorbed phosphorus, and the spent media is recycled as an agricultural soil amendment.

What’s Next

Merkelbach said SWIG technology is simple to construct and operate and can be easily scaled, which allows it to be replicated elsewhere in Florida, where the company has operated since 2017.

With no chemical additives and producing no waste, it is applicable in both urban and rural settings. With recent regulations passed by the Florida Legislature, the technology could also apply to stormwater systems to provide enhance treatment to meet new standards.

“SWIG is uniquely positioned to provide custom nutrient removal products and systems throughout Florida to meet new water quality rules and the continued impacts of rapid population growth.”

PROJECT TIMELINE:

August-October 2019 – Project design and environmental resource permit (ERP) preparation.

November 2019 – Project ribbon cutting ceremony with the District and SWIG, obtain ERP. Replace project contractor and SWIG to become the general contractor.

December 2019 – PES Media preparation offsite and site utility survey. Confirm media infiltration rate and media P removal rate.

January 2020 – Site grading and transport media to the project site.

February 2020 – Constructed the gravel underdrain and media bed. Install wetland vegetation. Rinsed PES with plant water to remove fines and sample results confirm 93% removal.

March 2020 – Finalize pump station installation and electrical controls

April 2020 – System operations and monthly invoices to SJRWMD.

January 2026 – Funding extension date.