STAFF & WIRE REPORTS

US Patent Office grants Tersus a New Patent. Authors of the newly issued patent are Gary Birk, Florida-Licensed Professional Engineer and David Alden.

The U.S. Patent and Trademark Office has issued patent US 11,577,231 B2 (the ‘231 patent) to Tersus Environmental. Officially granted on Feb. 14, 2023, the ‘231 patent is titled “Enhanced Reduction Bioremediation Method Using In Situ Alcoholysis.”

Authors for the newly issued ‘231 patent are Gary Birk, PE and David Alden.

This patent further strengthens the company’s intellectual property coverage for the diverse selection of products and technologies addressing the remediation of contaminated soils and aquifers.

Anaerobic in situ remediation has emerged in recent years as a viable and cost-effective remediation strategy for recalcitrant contaminants.

The process is used to modify chemical, physical, and biological conditions in soil and groundwater to facilitate degradation of a broad range of contaminants under anaerobic conditions to harmless end-products.

Contaminants include chloroethenes, chloroethanes, chloromethanes, chlorinated cyclic hydrocarbons, oxidized metals (e.g., hexavalent chromium (Cr [VI]), selenium (VI), uranium [VI]), various energetics (e.g., perchlorate, RDX, TNT), and nitrate.

In the case of anaerobic reductive dechlorination, the bacteria gain energy and grow as one or more chlorine atoms on a chlorinated hydrocarbon are replaced with hydrogen in an environment devoid of oxygen.

The contaminant (i.e., chlorinated compound, typically a chlorinated solvent) serves as the electron acceptor and hydrogen serves as the electron donor. Anaerobic reducing conditions are created by the addition of a readily assimilable carbon source, organic substrate to the environmental media.

The assimilable carbon source is used as food by native, or introduced, microbes and provides the hydrogen needed by dechlorinating organisms.

Emulsified vegetable oil (EVO) is often used as an assimilable carbon source as it slowly ferments and can act in the subsurface as an organic carbon and hydrogen source that stimulates organohalide-respiring bacteria that, in turn, mineralize chlorinated solvents.

Although emulsifying vegetable oil allows overcoming limitations of pure vegetable oil injection and minimizes field interventions by using a long-lasting electron donor, hundreds of EVO injection events over the past years have demonstrated that EVO effects are limited to the area in the immediate vicinity of the injection point.

This is evident through low TOC values measured even tens of meters downgradient to injection points where only acetic acid predominates.

A favorable fatty acid diversity seems to be limited to the injection point’s immediate vicinity (< 5 meters).

Another inconvenience that becomes more evident when using permanent, screened wells, is biofouling.

This phenomenon is typically attributed to biomass developing in the aerobic vicinity of injection wells due to hydrophobic oils creating a film (residual electron donor) that stimulates biomass growth.

In many cases, biofouling, or permeability losses, could very well be attributed to geochemical incompatibilities between EVO and cations in the subsurface, or EVO’s intrinsically high retention to soils.

The ’231 patent is the accumulation of years of research and development to overcome two of the main challenges associated with EVO injection: poor fatty acid subsurface distribution and biofouling.

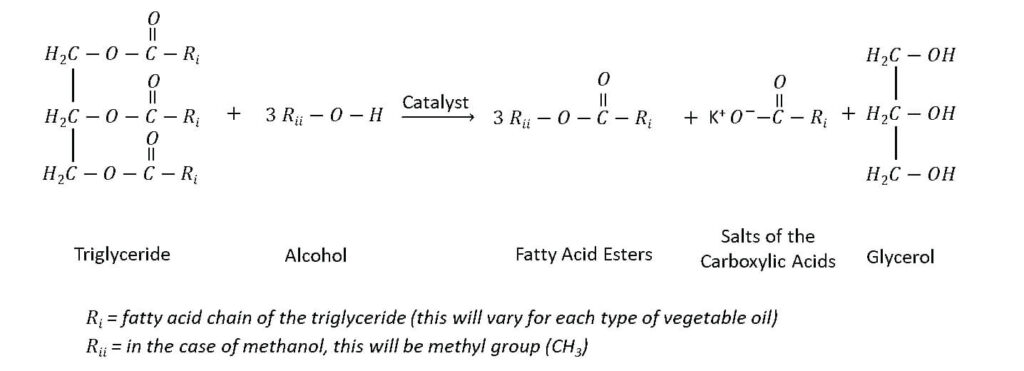

The ‘231 patent claims are generally directed towards, but not limited to, transesterification of vegetable oils to improve formation and distribution of slowly fermenting and soluble electron donors that are essential to anaerobic reductive bioremediation within the environmental medium.

Recent field work for the treatment of halogenated, volatile organic compounds has demonstrated that in situ alcoholysis reactions can treat more than 90% of the contaminant mass within 90 days.

The ‘231 patent claims further include methods for heating the soil or aquifer. Tersus Environmental’s current R&D efforts are focused on developing cost effective methods for applying heat.

The reaction temperature significantly influences the transesterification reaction. Heating the soil or aquifer further increases the alcoholysis reaction rates.●